GetSmart: Innovative Reverse Logistics Warehouse Services, Designed for Life

Role: Project Lead

Project: GetSmart

Background

Supply chain logistics is a fast-paced world where every minute counts, and efficiency becomes the heartbeat of success. In this dynamic realm, orchestrating processes and allocating resources plays a pivotal role in shaping outcomes. It's a landscape where innovation can make the difference between thriving and merely surviving. The initiative I spearheaded, known as GetSmart, in my capacity as Sr. Experience Manager and Project Lead, illustrates the trajectory that shifted skeptics into enthusiastic collaborators and showcases the intricate choreography of aligning business objectives with the needs of both customers and employees. As we progressed through this transformative endeavor, the journey itself evolved into a testament to the potency of harmonizing stakeholders across all tiers with a strategic vision, empathy, and an unwavering pursuit of excellence in every facet of the WWT's reverse-logistics ecosystem.

Business Rationalization

WWT's Electronic Procurement & Logistics (ePL) division had been delivering on a multi-year program for a large telecommunications customer to receive, store, refurbish or retire, and redeploy hardware the customer had deployed across the region. This customer had recently significantly increased the volume of items being processed through this program and with the vast increase in volume, the customer also saw their costs increase significantly. The customer requested that WWT conduct an audit on their reverse-logistics operations to identify areas opportunities to reduce costs through process efficiencies and through co-investment in warehouse 5G technology innovation. This created a unique opportunity for WWT to not only showcase its culture and consulting services with a significant client, but also to prove itself as a valuable technology and innovation partner.

What is Reverse Logistics?

Reverse logistics is the process of retrieving field-deployed items, shepherding them back to a warehouse for storage, refurbishment, redeployment, or disposal. Unlike the streamlined flow of new product logistics, characterized by neatly packaged uniform orders, reverse logistics deals with the complexities of moving a large variety of intermixed technologies deployed across large geographical regions. This process frequently leads to pallets filled with a variety of items that are more than occasionally haphazardly stacked. This intricate cycle underscores the importance of efficiency and strategic innovation in managing the dance between product usage and reintegration into the field.

Kickoff & Visioning: Navigating the Stakeholder Landscape

Mapping Stakeholders in Expansive Supply Chain Dynamics

With a workforce exceeding 9000 and a substantial portion of the company's revenue intertwined with supply chain operations, the task of identifying pertinent stakeholders emerged as a formidable challenge. The intricate interplay of interests, apprehensions, and viewpoints spanning business leadership, people leaders, and subject matter experts presented a complex landscape that necessitated a methodical approach for pinpointing and engaging the most fitting participants.

Identifying “the right” stakeholders across business leadership, people leaders, subject matter experts, and project delivery was vital to driving the initiative's success. WWT's supply chain products and services account for over 70% ($12B) of its annual revenue and over 85% of its 9000 employees. With such broad and large-scale potential impacts on the business, it was crucial to gain a comprehensive understanding of the intricate web of interests, concerns, and perspectives of each stakeholder group.

I successfully accomplished this in two ways:

- I identified the people and program leaders that were most closely related to the warehouse teams we would be researching and sorted them by their hierarchical level in the company and the length of time they had been employed with WWT. I then scheduled quick conversations with the middle-management leaders that had been with WWT the longest, asking them probing questions and discovering who in the supply chain organization would have an interest in our initiative.

- With a comprehensive list of potential stakeholders for our initiative, I scheduled a “Pre-Kickoff” meeting where I used my custom-developed Mt. Everest stakeholder model to lead meeting attendees in determining their role in the initiative and identifying any additional stakeholders. By having each stakeholder decide for themselves how involved they wanted to be in the initiative, we were able to set explicit engagement oversight expectations with Sponsors and Tacticians while empowering a sense of ownership and autonomy for Interpreters and Sherpas that translated into a more meaningful and impactful collaboration.

This analysis and collaborative stakeholder engagement formed the foundation of the team's communication strategy and risk management, ensuring that actions were not only well-informed but also responsive to the needs of those involved or impacted. Now that we had identified the relevant stakeholders, we faced another looming challenge.

Resistance to Participation

The task of rallying skeptical stakeholder groups to not only join the initiative but also actively contribute their insights introduced an additional challenge to our stakeholder strategy. Within each stakeholder segment, experience with multiple previously failed initiatives had bred skepticism regarding whether any kind of transformation was possible. Through my concerted efforts, the journey from skepticism to enthusiasm was paved, converting doubters into enthusiastic advocates of the transformative cause.

The challenge lay in addressing each stakeholder's reservations, illustrating the worth of their engagement, and spotlighting the potential benefits to them personally, their teams, and the entire operation. This necessitated a skillful exercise of persuasive communication, coupled with the aptitude to synthesize their perspectives and expectations into a singular strategy.

Aligning GetSmart's strategy, including its vision, mission, and objectives with each stakeholder's perspectives, aspirations, and expertise, ensured a symbiotic relationship between the project's goals and the interests of those who would contribute to its success. This tailored alignment not only cultivated a shared sense of purpose but also fueled a collective drive toward the transformation of supply chain warehouse ecosystems.

Research: Earning Warehouse Employee Trust

Overcoming a Low Trust Environment

Adding to the difficulty of innovating warehouse systems and processes was a well-deserved warehouse culture of low trust. Here, a history of failed sweeping process changes loomed large in the memory of long-time warehouse employees. These employees had been around the block and had firsthand experience of having their feedback brushed aside, then working double shifts for weeks, cleaning up after disastrous top-down process “improvements” they knew weren't going to work. The challenge of building rapport, establishing trust, and creating an environment where employees felt comfortable divulging candid feedback was no easy task. It was going to require not only a profound understanding of the sensitivities involved but also the application of empathy to forge personal connections. Our approach needed to ensure their voices were not just heard but deeply valued.

Prior to reaching out to various warehouse floor teams, I expected that for most warehouse employees their biggest concern would be the fear of saying or doing something their team leads and managers would not be happy with, leading to negative outcomes for themselves and their teammates. I couldn't have been more wrong. As it turned out, the warehouse floor employees LOVED their team leads and managers and were most afraid of the potential disruptions we were going to cause. It was obvious that the key to gaining warehouse floor employees' trust lay not in the promise of anonymity and safety from retribution but in first establishing strong relationships built on genuine respect and transparency with the people they trusted most.

Thankfully, this wasn't too difficult to accomplish. As I previously mentioned, many warehouse employees had been through multiple rounds of failed top-down process “improvement” initiatives. In each of these instances, they could have told you where and why the “improvements” were going to fail, but no one had ever thought to ask them. What a tragedy. With my deep experience in user-focused research and technology solutioning, I knew our only chance to successfully deliver truly transformative changes was to:

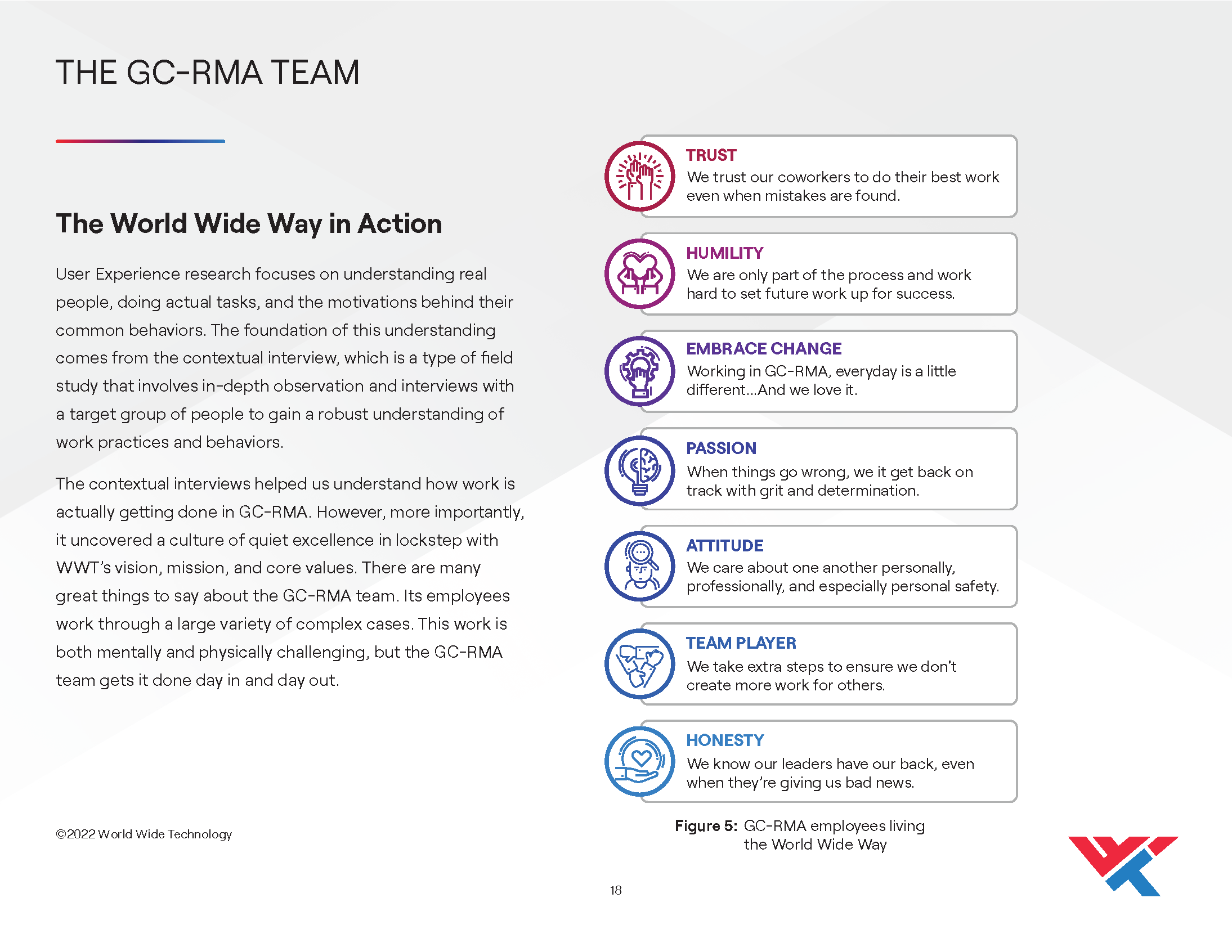

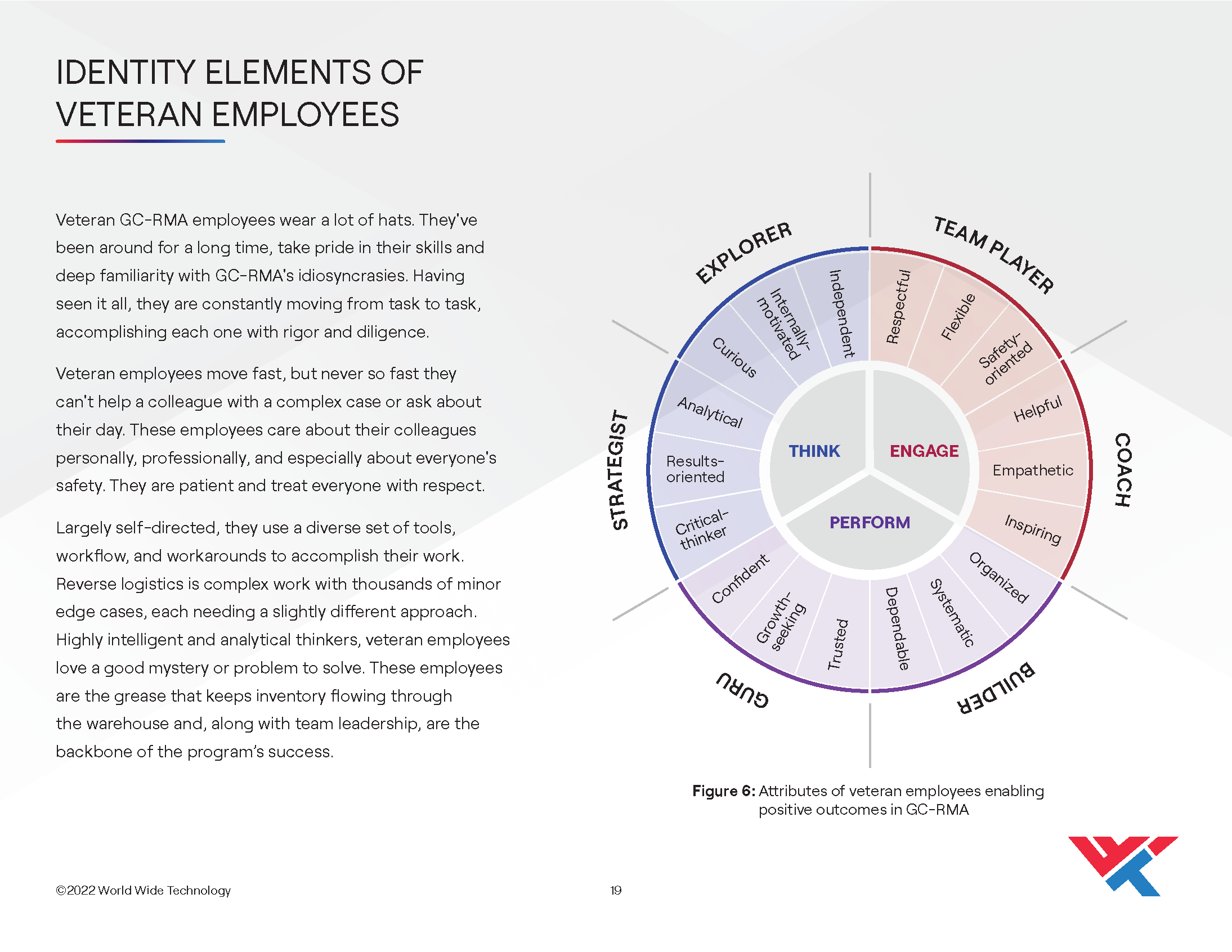

1. Identify, align, and elevate the people and personality traits that formed the bulwark of the reverse-logistics program so far.

2. Then establish an environment of mutual respect and collaboration, where their input wasn't just welcomed, but actively sought after.

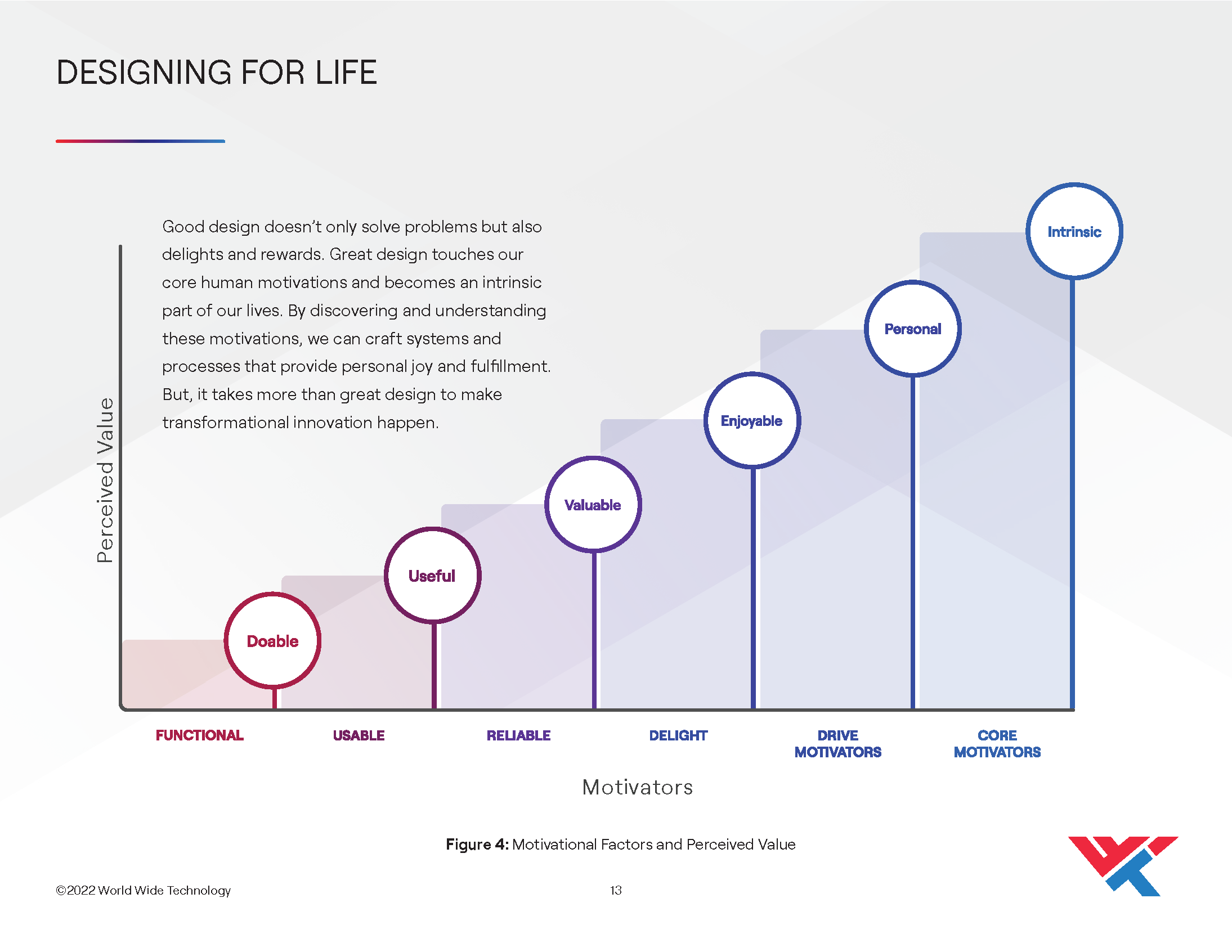

Pioneered by Hugh Beyer and Karen Holtzblatt and taught at Carnegie Mellon, Contextual Design stems from the realization that individual products and services only deliver a part of a larger picture value and are always used within broader contexts of the customer's journey through life. So, good product/service design is really about the redesign of the customer's life. It's about designing a new and better way for the customer to live their life, touch the people that matter to them, and achieve their goals. In other words, it's “Designing for Life.”

At the heart of the Contextual Design process is a form of ethnographic research, the contextual inquiry. Contextual inquiries serve as an invaluable compass in the realm of user-centric design. Rooted in the philosophy of understanding and empathy, this approach goes beyond data collection, delving into the nuanced context of individuals' lives, needs, and aspirations. By immersing ourselves in the daily rhythms and routines of warehouse employees, we not only gathered insights but also signaled a profound respect for their perspectives. This process of active engagement ensured that participants felt their perspectives were not only heard but also deeply valued. The personal connections forged through ethnographic research enriched our understanding, enabling us to design solutions that resonated authentically and made a genuine impact on the lives of those we serve.

Solutioning: Innovating Successfully

Innovation in Complex Supply Chain Ecosystems

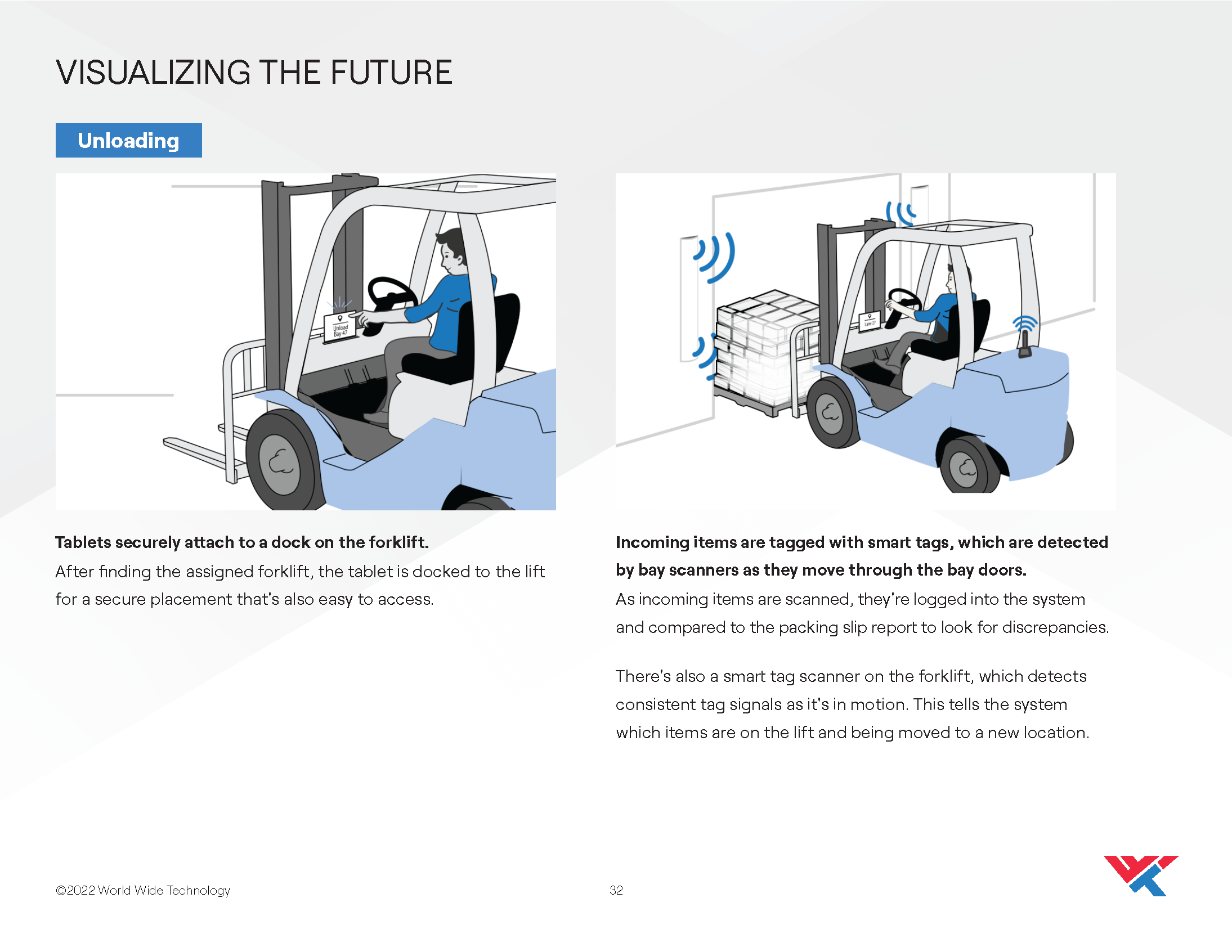

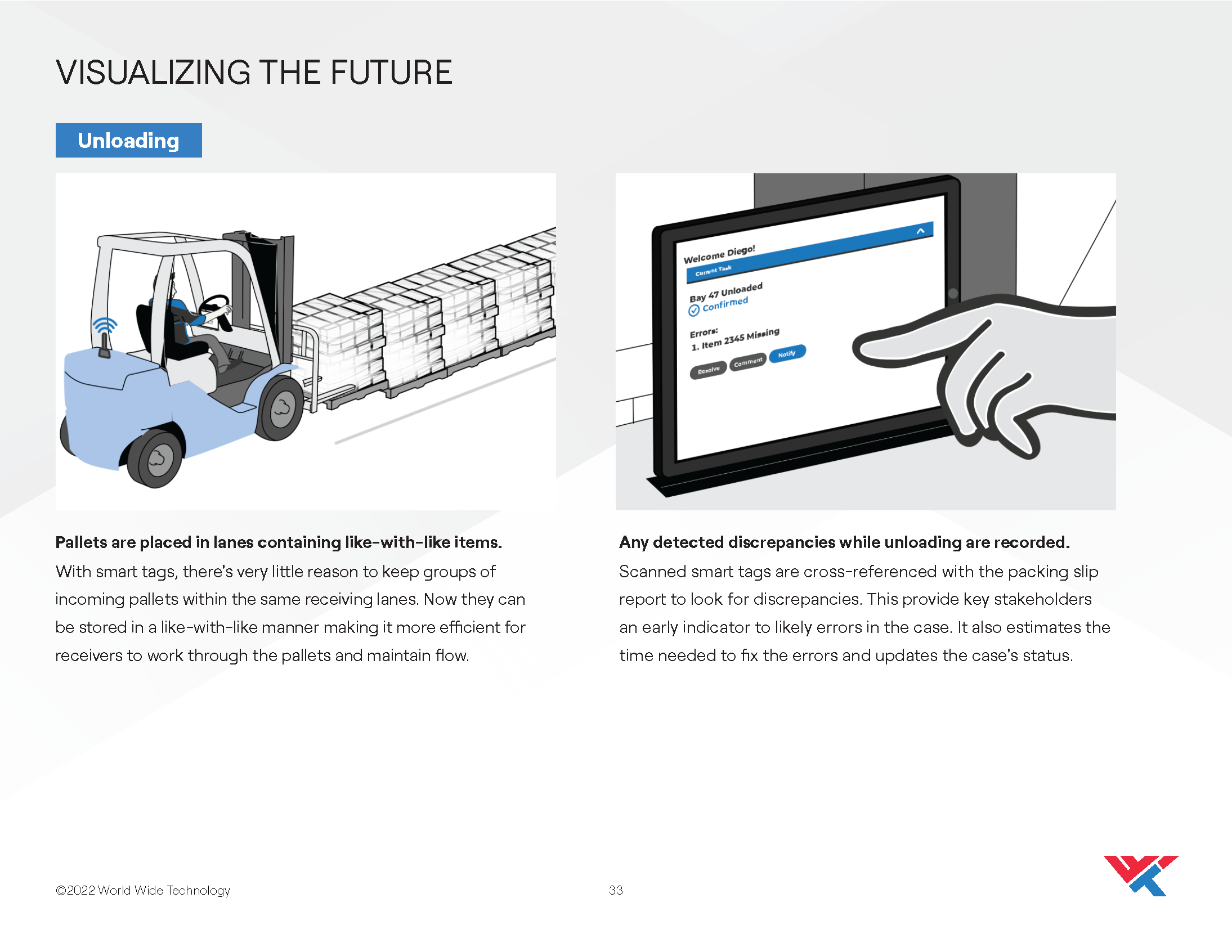

Innovating within complex supply chain systems and large organizations presents distinct challenges. Forcing innovation onto unwilling employees is doomed to fail due to resistance and disconnect. Introducing innovations beyond the organization's capability leads to unattainable outcomes. Similarly, innovations misaligned with business strategies and culture are destined to falter. Success hinges on innovations that are viable for the business, technologically feasible, and desirable to the people who interact the most with it, ensuring innovation drives meaningful transformation rather than becoming an empty endeavor.

The innovation sweet spot exists where an organization's technical capabilities meet real-world customer needs while delivering on the organization's strategic goals. This concept is valuable to organizations and teams because it helps focus their efforts and resources on the areas that have the highest chance of succeeding and making an impact. By aligning technical capabilities with tangible customer needs and overarching strategic objectives, we were able to elevate the ideas that maximized the utility of the organization's resources, enhanced market competitiveness, and facilitated the creation of solutions that resonated with both warehouse employees and the broader business goals.

Conclusion

Successfully overcoming all the above challenges demanded a blend of strategic leadership, effective communication, and a commitment to the principles of user-centered design. By addressing these obstacles head-on and with a keen focus on stakeholder engagement and empathy-driven research, the GetSmart initiative was able to navigate the complexities of innovation and achieve its transformative goals. The process stands as a testament to the power of persistence, adaptability, and the unwavering dedication to achieving the delicate balance between business objectives and the needs of customers and employees.

In the journey to optimize the warehouse reverse logistics program, the blend of stakeholder management, contextual design concepts, and targeting viable, feasible, and desirable innovation proved to be the catalyst for transformation. This case study highlights not only my expertise in people-focused technology solutions but also the power of aligning business goals with empathy and user-centered design values. Throughout this journey, I was able to lead my team and the supply chain organization in discovering innovative solutions that not only resonated with the customer and warehouse employees but also provided WWT with a competitive advantage in the market.